Emulsion Polymer Market Expands with Innovations in Low-VOC Solutions, Advanced Formulations, and Regional Production to Meet Rising Industry Demand.

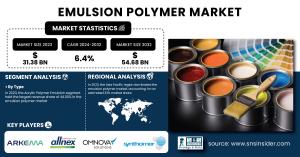

AUSTIN, TX, UNITED STATES, February 4, 2025 /EINPresswire.com/ -- The Emulsion Polymer Market size was valued at USD 31.38 Billion in 2023 and is projected to reach USD 54.68 Billion by 2032, growing at a CAGR of 6.4% over the forecast period 2024-2032.The rising adoption of emulsion polymers in the paints & coatings industry, coupled with growing infrastructure projects worldwide, further propels market growth.

Get a Sample Report of Emulsion Polymer Market @ https://www.snsinsider.com/sample-request/1435

The major factors driving the emulsion polymer market are likely to include the change to green and sustainable materials.

Emulsion polymers such as acrylics, styrene-butadiene (SB) latex, and vinyl acetate are key ingredients in many water-based paints, coatings, and adhesives due to low environmental impact and desirable performance properties.

The demand for emulsion polymers is majorly driven due to the expansion of construction and automotive industries. The growing use of water-based paints and coatings incorporating emulsion polymers such as methyl methacrylate (MMA)-based are replacing solvent-based counterparts, which have higher VOC emissions in accordance with global environmental policies.

Also, government regulations supporting green chemistry & sustainable products drove the market growth. Limited VOC content assisting its continuity from strong regulations by regulatory bodies i.e. U.S Environmental Protection Agency (EPA) and European Chemicals Agency (ECHA) continues to promote product development in emulsion polymer market.

Emulsion polymers have been improved in its functional by recent developments of polymerization technologies. Growth in the demand for emulsion polymers across industries, particularly in sectors like packaging, textiles and healthcare, is estimated to drive substantial adoption of emulsion polymers for barrier coatings and nonwoven fabrics (including those used in hygiene products.

Key Players:

• Synthomer (Synthomer 3341, Synthomer 5790)

• OMNOVA Solutions (Versaflex® 101, Covinax® 1810)

• Allnex GMBH (Rheobuild® 1000, Beckosol® 66)

• Arkema (Coatex® 110, Rhodopas® 260)

• DIC CORPORATION (DIC-EMUL® 8050, DIC-EMUL® 1010)

• BASF SE (Acresin® 600, Joncryl® 678)

• Celanese Corporation (Vinac® 1535, Celvol® 530)

• Wacker Chemie AG (Vinnapas® 2050, Elastodur®)

• Momentive (Silres® BS 100, Momentive® EPX 1000)

• Mallard Creek Polymers (MC-509, MC-504)

• Solvay (Rhovanil®, Rheomer® 10)

• Clariant (Dispersogen® S-200, Hostaflon® PFPE)

• Asahi Kasei Corporation (S-LEC®, Alpolic®)

• BATF Industry Co., Ltd. (BATF 8610, BATF 8800)

• JSR Corporation (JSR-4100, JSR 1010)

• Koninklijke DSM N.V. (NeoCryl® A-1079, NeoCryl® A-2000)

• Shanxi Sanwei Group Co., Ltd. (SSW-2210, SSW-3220)

• Dow (Dow Latex 250, Dow Latex 543)

• Trinseo S.A. (NeoCryl® A-1079, Toughseal® 9000)

• Wacker Chemie AG (Vinnapas® 8000, Elastodur® 9000)

Segmentation Analysis

By Type

• Acrylic Polymer Emulsion

• Vinyl Acetate Polymer Emulsion

• SB Latex

• Others

Acrylics held the largest market share around 44% share of the overall market in 2023.

Acrylic emulsion polymers are effectively used in films for paints, coatings, adhesives, and textiles under aqueous environments because their compelling water, staying power, and UV strength. The growth in the use of these materials in architectural and industrial coatings coincide with the trend towards waterborne, low-VOC formulations meeting stricter environmental regulations. Moreover, continuous improvement in polymer technology has also led to the development of acrylic emulsions with higher adhesion, gloss retention, and flexibility, which has significantly bolstered the growth of this end-use segment. Acrylics have also dominated the market, primarily due to the booming construction and automotive sectors, especially in Asia-Pacific and North America.

Styrene-Butadiene (SB) Latex segment is anticipated to be the fastest-growing product type over the forecast period. SB latex is widely employed in synthetic rubber, adhesive, and paper coatings industries. Segment Growth is due to the growing use of SB latex in packaging and construction industries

By Application

• Paints & Coatings

• Adhesives & Sealants

• Paper & Paperboard

• Others

Paints & Coatings held the largest segment in the emulsion polymer market, with a share of 42.00% of emulsion polymer global revenue in 2023.

The growth is driven by the increasing demand of water-based minimal-VOC coatings from construction, automotive, and industrial end-use industries. Similarly, firms such as PPG Industries and AkzoNobel have come up with new ideas that cover their as well as other sustainability and performance and Film or coatings requirements.

By End-Use Industry

• Building & Construction

• Automotive

• Chemicals

• Textile & Coatings

Buy Full Research Report on Emulsion Polymer Market 2024-2032 @ https://www.snsinsider.com/checkout/1435

Regional Analysis

Asia-Pacific

The Asia Pacific region was the largest market emulsion polymer, with estimated read of around 33% in 2023. This supremacy is primarily attributed to the speedy Industrialization, Urbanization as well as the Infrastructure Development mainly in China, India and the other Southeast Asian nations. The emulsion polymers market, particularly in paints, coatings, and adhesives, is driven by high growth rates in construction, automotive, and packaging segments across the region. For instance, BASF and Arkema among others poured resources into new Asian production capacity to take advantage of the appetite for water-based, environmental solutions and solidified the top position.

North America, held the significant growth in the market and in North America the U.S. held the largest share particularly, due to the growing demand for low-VOC coatings along with stringent environmental regulations and innovation in polymerization technologies are some of the drivers fuelling the market growth. Market growth is additionally supported by gaps in key players emphasizing activities related to R&D concerning bio-based emulsion polymers.

Recent Developments

• May 2024: BASF launched a new range of bio-based acrylic emulsion polymers designed for high-performance coatings and adhesives, aligning with the growing demand for sustainable solutions.

• April 2024: Dow Chemicals introduced an innovative SB latex formulation with enhanced durability and water resistance, targeting applications in construction and automotive coatings.

• March 2024: Arkema expanded its emulsion polymer production capacity in Asia-Pacific to meet the rising demand for water-based coatings in the region.

Speak with Our Expert Analyst Today to Gain Deeper Insights @ https://www.snsinsider.com/request-analyst/1435

About Us:

SNS Insider is a global leader in market research and consulting, shaping the future of the industry. Our mission is to empower clients with the insights they need to thrive in dynamic environments. Utilizing advanced methodologies such as surveys, video interviews, and focus groups, we provide up-to-date, accurate market intelligence and consumer insights, ensuring you make confident, informed decisions.

Jagney Dave

SNS Insider Pvt. Ltd

+1 315 636 4242

email us here

Visit us on social media:

Facebook

X

LinkedIn

Instagram

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.