Connected power tools mark a pivotal shift in industrial operations. As smart factories grow, IoT-enabled tools will become essential for precision, uptime, and cost control.”

NEWARK, DE, UNITED STATES, May 13, 2025 /EINPresswire.com/ -- 𝐈𝐧𝐭𝐫𝐨𝐝𝐮𝐜𝐭𝐢𝐨𝐧 𝐭𝐨 𝐭𝐡𝐞 𝐄𝐯𝐨𝐥𝐯𝐢𝐧𝐠 𝐏𝐨𝐰𝐞𝐫 𝐓𝐨𝐨𝐥 𝐋𝐚𝐧𝐝𝐬𝐜𝐚𝐩𝐞— Nikhil Kaitwade, Associate Vice President at Future Market Insights

The global power tool market has long been characterized by innovations in energy efficiency, cordless technology, and ergonomic design. These elements have shaped consumer demand and manufacturer strategies for decades. However, a subtle yet impactful shift is emerging—one that is reshaping the industrial landscape more quietly than flashy battery innovations or rugged tool casings. The integration of Internet of Things (IoT) and smart connectivity into power tools is ushering in a new phase of industrial productivity, safety, and asset management. Despite its transformative potential, this development remains underrepresented in mainstream market discussions.

𝐓𝐡𝐞 𝐑𝐢𝐬𝐞 𝐨𝐟 𝐈𝐨𝐓 𝐢𝐧 𝐏𝐨𝐰𝐞𝐫 𝐓𝐨𝐨𝐥𝐬: 𝐀 𝐐𝐮𝐢𝐞𝐭 𝐑𝐞𝐯𝐨𝐥𝐮𝐭𝐢𝐨𝐧

IoT integration in power tools extends far beyond novelty. It involves embedding sensors, wireless communication modules, and microcontrollers into tools to create an ecosystem of data-driven operations. These smart tools can collect information such as usage patterns, tool location, torque levels, and maintenance needs. This data is then transmitted to cloud platforms or mobile apps, allowing real-time monitoring and predictive analytics.

𝐌𝐚𝐤𝐞 𝐈𝐧𝐟𝐨𝐫𝐦𝐞𝐝 𝐃𝐞𝐜𝐢𝐬𝐢𝐨𝐧𝐬 – 𝐀𝐜𝐜𝐞𝐬𝐬 𝐘𝐨𝐮𝐫 𝐒𝐚𝐦𝐩𝐥𝐞 𝐑𝐞𝐩𝐨𝐫𝐭 𝐈𝐧𝐬𝐭𝐚𝐧𝐭𝐥𝐲! https://www.futuremarketinsights.com/reports/sample/rep-gb-760

One prominent example is Milwaukee Tool’s ONE-KEY platform, which allows users to customize tool settings, track tool usage, and even lock tools remotely if stolen or lost. Similarly, DEWALT’s Tool Connect™ ecosystem provides Bluetooth-based tracking and tool diagnostics, giving managers better control over fleet health and worker productivity. These innovations demonstrate that the power tool market is no longer just about cutting, drilling, or fastening—it’s about optimizing workflows and maximizing ROI in industrial settings.

𝐈𝐧𝐝𝐮𝐬𝐭𝐫𝐢𝐚𝐥 𝐀𝐩𝐩𝐥𝐢𝐜𝐚𝐭𝐢𝐨𝐧𝐬 𝐚𝐧𝐝 𝐒𝐦𝐚𝐫𝐭 𝐅𝐚𝐜𝐭𝐨𝐫𝐢𝐞𝐬: 𝐑𝐞𝐚𝐥-𝐖𝐨𝐫𝐥𝐝 𝐄𝐱𝐚𝐦𝐩𝐥𝐞𝐬

In manufacturing, aerospace, and construction industries, where precision and uptime are paramount, smart power tools are proving to be game-changers. In one notable use case, a European aerospace company integrated Bosch’s Connected Control system into its torque wrenches to maintain strict calibration standards. The connected system not only ensured consistent fastening but also generated compliance logs automatically, reducing manual inspection time by nearly 30%.

In smart factories, power tools with IoT capabilities feed into centralized control systems, allowing supervisors to view tool performance dashboards across assembly lines. Predictive maintenance is another key advantage. When a high-torque drill begins to show early signs of motor wear, smart diagnostics can alert the operator before failure occurs—averting potential downtime and expensive replacements. These operational insights offer a clear edge to manufacturers operating in highly competitive, high-precision sectors.

𝐂𝐡𝐚𝐥𝐥𝐞𝐧𝐠𝐞𝐬 𝐚𝐧𝐝 𝐑𝐨𝐚𝐝𝐛𝐥𝐨𝐜𝐤𝐬 𝐢𝐧 𝐀𝐝𝐨𝐩𝐭𝐢𝐨𝐧

Despite its advantages, the path to widespread adoption of IoT-enabled power tools is not without hurdles. One of the primary challenges is cost. Connected tools typically carry a premium, making them less attractive to price-sensitive segments like residential users or small contractors. Additionally, the need for IT infrastructure, data security, and technical training in the workplace can be deterrents, especially in regions where digital literacy in trades is still maturing.

𝐔𝐧𝐥𝐨𝐜𝐤 𝐂𝐨𝐦𝐩𝐫𝐞𝐡𝐞𝐧𝐬𝐢𝐯𝐞 𝐌𝐚𝐫𝐤𝐞𝐭 𝐈𝐧𝐬𝐢𝐠𝐡𝐭𝐬 – 𝐄𝐱𝐩𝐥𝐨𝐫𝐞 𝐭𝐡𝐞 𝐅𝐮𝐥𝐥 𝐑𝐞𝐩𝐨𝐫𝐭 𝐍𝐨𝐰: https://www.futuremarketinsights.com/reports/power-tools-market

Compatibility with existing systems also poses issues. Many legacy manufacturing operations lack the digital framework required to fully leverage the capabilities of smart tools. Furthermore, the perceived complexity of managing a connected tool fleet, ranging from software updates to data privacy compliance—can overwhelm smaller firms with limited resources.

𝐑𝐞𝐠𝐢𝐨𝐧𝐚𝐥 𝐈𝐧𝐬𝐢𝐠𝐡𝐭𝐬: 𝐖𝐡𝐞𝐫𝐞 𝐈𝐧𝐧𝐨𝐯𝐚𝐭𝐢𝐨𝐧 𝐢𝐬 𝐀𝐜𝐜𝐞𝐥𝐞𝐫𝐚𝐭𝐢𝐧𝐠

Not all regions are progressing at the same pace when it comes to adopting smart power tools. North America and Western Europe currently lead in terms of both product availability and deployment across industrial sectors. In the U.S., construction firms are increasingly integrating digital tools as part of broader building information modeling (BIM) workflows, linking power tool telemetry with architectural data to improve construction accuracy and reduce rework.

In Asia-Pacific, particularly in Japan and South Korea, smart factories are driving demand for connected power tools in electronics and automotive manufacturing. Meanwhile, in the Middle East, where large-scale infrastructure projects are surging, governments are pushing for digital transformation in construction, opening new avenues for smart power tool adoption.

𝐅𝐮𝐭𝐮𝐫𝐞 𝐎𝐮𝐭𝐥𝐨𝐨𝐤: 𝐖𝐢𝐥𝐥 𝐒𝐦𝐚𝐫𝐭 𝐓𝐨𝐨𝐥𝐬 𝐁𝐞𝐜𝐨𝐦𝐞 𝐭𝐡𝐞 𝐍𝐞𝐰 𝐒𝐭𝐚𝐧𝐝𝐚𝐫𝐝?

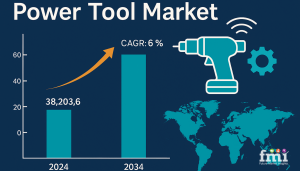

The momentum for smart, connected tools is building, and the question is not whether they will become standard—but when. According to Future Market Insights, the power tool is projected to have a steady CAGR of 6% during the period 2024 to 2034. It is estimated to grow from USD 38,203.6 million in 2024 to USD 68,418.8 million in 2034, driven by the convergence of AI, cloud computing, and advanced manufacturing practices. As digital twins, augmented reality, and robotics continue to shape industrial workflows, smart power tools will form the connective tissue between physical labor and digital oversight.

Manufacturers who ignore this trend may find themselves outpaced not just in terms of technology but also in efficiency, safety, and regulatory compliance. The shift toward data-centric tool management is not just a passing phase—it’s an industrial imperative.

𝐓𝐨𝐨𝐥𝐬 & 𝐀𝐜𝐜𝐞𝐬𝐬𝐨𝐫𝐢𝐞𝐬 𝐈𝐧𝐝𝐮𝐬𝐭𝐫𝐲 𝐀𝐧𝐚𝐥𝐲𝐬𝐢𝐬: https://www.futuremarketinsights.com/industry-analysis/tools-and-accessories

𝐊𝐞𝐲 𝐒𝐞𝐠𝐦𝐞𝐧𝐭𝐬 𝐨𝐟 𝐏𝐨𝐰𝐞𝐫 𝐓𝐨𝐨𝐥

By Product Type:

In terms of products, the industry is divided into drilling tool, fastening tool, heat gun, angle grinder, chain saw, orbital sander, jigsaw, impact wrench, and circular saw.

By Technology:

In terms of technology, the industry is segmented into electric and pneumatic tools. The electric segment is further classified into corded, and cordless. The cordless segment is segregated into li-ion battery, lead acid battery, and others (Ni-Cd, Ni-Mh).

By Sales Channel:

In terms of sales channel, the industry is divided into online and offline.

By Application:

In terms of application, the industry is segregated into manufacturing, MRO services, DIY, and construction. The manufacturing segment has been further grouped into metal fabrication, automotive, railways, aerospace, furniture, and others. The MRO services segment is segregated into facility management, automotive, aerospace, and other industrial.

By Region:

Key countries of North America, Latin America, Western Europe, Eastern Europe, East Asia, South Asia Pacific, and Middle East and Africa (MEA) have been covered in the report.

𝐑𝐞𝐥𝐚𝐭𝐞𝐝 𝐑𝐞𝐩𝐨𝐫𝐭𝐬:

Electric Hedge Trimmer Market: https://www.futuremarketinsights.com/reports/electric-hedge-trimmer-market

Hedge Trimmers Market: https://www.futuremarketinsights.com/reports/hedge-trimmers-market

High Speed Steel (HSS) Tools Market: https://www.futuremarketinsights.com/reports/hss-tools-market

Galvanic Isolation Market: https://www.futuremarketinsights.com/reports/galvanic-isolation-market

Power Tool Gears Market: https://www.futuremarketinsights.com/reports/power-tool-gears-market

𝐀𝐛𝐨𝐮𝐭 𝐅𝐮𝐭𝐮𝐫𝐞 𝐌𝐚𝐫𝐤𝐞𝐭 𝐈𝐧𝐬𝐢𝐠𝐡𝐭𝐬 (𝐅𝐌𝐈)

Future Market Insights, Inc. (ESOMAR certified, recipient of the Stevie Award, and a member of the Greater New York Chamber of Commerce) offers profound insights into the driving factors that are boosting demand in the market. FMI stands as the leading global provider of market intelligence, advisory services, consulting, and events for the Packaging, Food and Beverage, Consumer Technology, Healthcare, Industrial, and Chemicals markets. With a vast team of over 400 analysts worldwide, FMI provides global, regional, and local expertise on diverse domains and industry trends across more than 110 countries.

Join us as we commemorate 10 years of delivering trusted market insights. Reflecting on a decade of achievements, we continue to lead with integrity, innovation, and expertise.

𝐂𝐨𝐧𝐭𝐚𝐜𝐭 𝐔𝐬:

Future Market Insights Inc.

Christiana Corporate, 200 Continental Drive,

Suite 401, Newark, Delaware - 19713, USA

T: +1-347-918-3531

For Sales Enquiries: sales@futuremarketinsights.com

Website: https://www.futuremarketinsights.com

LinkedIn| Twitter| Blogs | YouTube

Ankush Nikam

Future Market Insights Global & Consulting Pvt. Ltd.

+ +91 90966 84197

email us here

Visit us on social media:

Other

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.