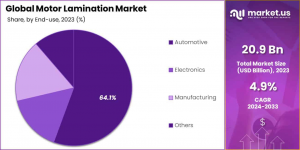

Motor Lamination Market is expected to be worth around USD 33.8 Bn by 2033, up from USD 20.9 Bn in 2023, and grow at a CAGR of 4.9% from 2024 to 2033.

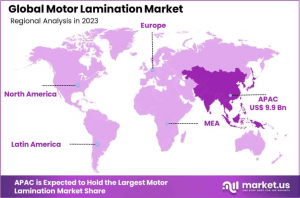

Asia-Pacific's Leadership in the Motor Lamination Market: Asia-Pacific holds a commanding lead in the motor lamination market with a 47.7% share, valued at USD 9.9 billion.”

NEW YORK, NY, UNITED STATES, January 24, 2025 /EINPresswire.com/ -- Report Overview— Tajammul Pangarkar

The Global Motor Lamination Market is witnessing a significant transformation driven by advancements in motor technologies and increasing demands for energy-efficient solutions. Motor laminations are critical components in the construction of motors and generators, serving to reduce eddy current losses through a laminated core. These components are prevalent across various sectors, including automotive, industrial, consumer electronics, and aerospace.

The motor lamination market is bolstered by the electrification of vehicles and the pervasive adoption of electric motors in industrial applications. With the automotive industry shifting towards electric vehicles (EVs), the demand for high-efficiency motors is escalating. This surge is further supported by global environmental policies and regulations that advocate for reduced greenhouse gas emissions, thereby propelling the need for advancements in motor efficiency. Moreover, the growing popularity of automation and robotics in the manufacturing sector is expanding the application range of motor laminations, making them indispensable in modern industrial machinery.

Driving factors for the motor lamination market include technological innovations, such as the development of ultra-high-strength steel laminations that offer superior performance and efficiency. The integration of IoT (Internet of Things) in the industrial and automotive sectors also plays a crucial role in this market’s growth, as it leads to the development of smarter and more efficient motor designs. Additionally, government initiatives aimed at promoting the use of energy-efficient appliances create a fertile environment for market growth. For instance, various subsidies and tax rebates offered for adopting green technologies are stimulating market demand.

The market faces challenges such as the high cost of raw materials and the need for significant investment in R&D to produce high-quality laminations. The fluctuating prices of steel, which is a primary raw material for motor laminations, pose a constant challenge to maintaining profit margins for manufacturers. Despite these challenges, manufacturers are increasingly focusing on research to develop cost-effective production methods that could mitigate the impact of raw material costs.

The future growth opportunities in the Global Motor Lamination Market are vast. With rapid advancements in technology, particularly in materials science and manufacturing techniques, there is potential for the development of lighter, more efficient lamination materials that could revolutionize motor design. The trend towards vehicle electrification and renewable energy applications provides a substantial growth platform for this market. Innovations such as the use of non-metallic materials for lamination, which can offer improved performance at lower weights, are expected to become more prevalent.

The expansion of the electric vehicle market globally, especially in emerging economies where urbanization and increasing consumer spending power are evident, offers additional growth prospects for motor laminations. The market is also likely to benefit from increased investments in smart grids and renewable energy installations, where efficient motors are essential for optimizing performance and reducing energy losses.

Discover detailed insights by accessing the sample through the provided link: https://market.us/report/motor-lamination-market/free-sample/

Key Takeaways

◘ The Global Motor Lamination Market is expected to be worth around USD 33.8 Billion by 2033, up from USD 20.9 Billion in 2023, and grow at a CAGR of 4.9% from 2024 to 2033.

◘ Welding technology holds a significant 43.2% share in the Motor Lamination Market.

◘ Cold-rolled lamination Steel is preferred, accounting for 46.4% of materials used.

◘ Battery Electric Vehicles (BEVs) dominate, comprising 58.1% of the electric vehicle type segment.

◘ Electrical stators and rotors are the main applications, capturing 59.1% of the market.

◘ The automotive sector is the largest end-user, with a substantial 64.1% market share.

◘ Asia-Pacific Leads Motor Lamination Market with 47.7% Share, USD 9.9 Billion.

Motor Lamination Top Trends

◘ Increased Use of Advanced Materials: The motor lamination market is moving towards using advanced materials like amorphous steel and high-grade electrical steel. These materials are chosen for their superior magnetic properties, which enhance motor efficiency by minimizing energy losses through better magnetic permeability and reduced core losses.

◘ Shift Towards Electric Vehicles (EVs): With the global shift towards electric mobility, there's a growing demand for motor laminations in EVs. This is driven by the need for more efficient electric traction motors, which are crucial for improving the range and performance of EVs.

◘ Focus on Energy Efficiency: Energy efficiency remains a key driver in the motor lamination market. There is a strong push, supported by regulatory mandates, to reduce energy consumption and enhance the performance of electric motors used in various applications from automotive to industrial machinery.

◘ Technological Innovations in Manufacturing: The market is also witnessing technological advancements in manufacturing processes such as laser cutting and additive manufacturing. These technologies enable the production of motor laminations with high precision and at lower costs, catering to the high-volume requirements of industries like consumer electronics and automotive.

◘ Integration of IoT and Smart Technologies: The integration of IoT and smart technologies into motor systems is becoming more prevalent. Motor laminations that support these technologies are being developed to enable real-time monitoring and efficiency optimization, which are key for applications in smart grids and modern industrial setups.

◘ Customization and High-Performance Solutions: There is a rising trend towards the customization of motor laminations to meet specific industry needs and performance requirements. This includes the development of laminations that are tailored for specialized applications in sectors like aerospace and high-performance electric vehicles, where durability and efficiency are critical.

Key Market Segments

Technology Analysis

Welding Technology: Dominating the Motor Lamination Market with a 43.2% share in 2023, welding is favored for its cost-effectiveness and precision. Its widespread adoption in manufacturing electric motors, especially for automotive and industrial applications, supports its leading position. The burgeoning demand for electric vehicle motors continues to propel the expansion of welding technology.

Material Analysis

Cold-Rolled Lamination Steel: This material commands a 46.4% market share, making it the preferred choice in 2023. Known for its high magnetic permeability and cost-efficiency, cold-rolled lamination steel is extensively utilized in electric motors. The increasing adoption of energy-efficient motors, paired with their compatibility with advanced manufacturing processes, underpins its market prominence.

Electric Vehicle Type Analysis

Battery Electric Vehicles (BEVs): Leading the segment with a 58.1% market share in 2023, BEVs are increasingly preferred due to the global shift towards zero-emission vehicles. Supported by government incentives and technological advancements in battery technology, BEVs are recognized for their efficiency and sustainability, suitable for both urban commuting and long-range transport.

Application Analysis

Electrical Stators and Rotors: These components are pivotal in the motor lamination market, holding a 59.1% share in 2023. As crucial elements of electric motors are used across automotive, industrial, and consumer sectors, the rise in electric vehicles and industrial automation is notably boosting their demand.

End-Use Analysis

Automotive Sector: As the predominant end-user, the automotive sector accounted for 64.1% of the market in 2023. The sector's growth is driven by the rapid adoption of electric vehicles, the increasing manufacture of fuel-efficient vehicles, and strict global emission regulations, highlighting the critical role of motor laminations in electric and hybrid vehicle powertrains.

Key Market Segments List

By Technology

-- Welding

-- Bonding

-- Stamping

By Material

-- Nickel Alloys

-- Cold-rolled lamination Steel

-- Cobalt Alloys

-- Silicon Steel

By Electric Vehicle Type

-- Battery Electric Vehicles

-- Hybrid Electric Vehicles

-- Plug-in Hybrid Electric Vehicles

-- Others

By Application

-- Electrical Stators and Rotors

-- Magnetic Coils

-- Transformers

By End-use

-- Automotive

-- Electronics

-- Manufacturing

-- Others

Regulations On the Motor Lamination Market

⦿ Emission and Energy Efficiency Standards: Governments worldwide are implementing stricter emission and energy consumption regulations. These standards drive the demand for energy-efficient motors in various sectors, including automotive and industrial applications, as these motors often use advanced motor laminations to minimize energy losses.

⦿ Environmental and Sustainability Regulations: Environmental regulations are pushing manufacturers towards more sustainable practices, including the use of recyclable materials and reduction of waste during the motor lamination manufacturing process. This trend is particularly strong in regions with stringent environmental policies.

⦿ Material and Manufacturing Standards: Specific regulations govern the materials and processes used in motor lamination production. For example, the quality of electrical steel used in laminations must meet high standards to ensure performance and efficiency, which is particularly crucial for applications in high-performance motors like those in electric vehicles.

⦿ Safety Standards in Automotive Applications: In the automotive sector, safety regulations influence motor design, including the lamination components. These regulations ensure that the motors perform reliably under various operating conditions, contributing to the overall safety of the vehicle.

⦿ Technological Advancements and Compliance: As technology advances, so do the regulations that ensure new technologies are safe, efficient, and environmentally friendly. This includes innovations in motor lamination techniques, such as improved bonding and stamping processes that offer greater precision and lower costs.

Save Up to 30% Today! https://market.us/purchase-report/?report_id=137734

Regional Analysis

Asia-Pacific's Leadership in the Motor Lamination Market: Asia-Pacific holds a commanding lead in the motor lamination market with a 47.7% share, valued at USD 9.9 billion. The region's dominance is bolstered by rapid industrialization and significant growth in automotive manufacturing, particularly in China, India, and Japan. The rise in electric vehicle adoption further fuels this growth.

North America's Strategic Position: Following Asia-Pacific, North America stands as a critical player, supported by advancements in renewable energy and a robust demand for energy-efficient motors. The United States and Canada are key contributors, driven by technological innovation and sustainable energy solutions.

Europe's Regulatory and Investment Strengths: In Europe, strict regulations on energy efficiency and substantial investments in electric mobility drive the market, with Germany, France, and the United Kingdom leading the charge. This region benefits from a proactive approach to adopting advanced motor technologies.

Emerging Markets in the Middle East & Africa: The Middle East & Africa region shows promising growth, spurred by investments in industrial automation and infrastructure development, particularly in the UAE and Saudi Arabia. This region is increasingly adopting modern motor solutions to boost its industrial capacities.

Latin America's Sectoral Expansion: Latin America, especially Brazil and Mexico, is experiencing growth through enhanced manufacturing capabilities and energy sector developments. The region is gradually integrating advanced motor technologies to improve efficiency and performance.

Key Players Analysis

-- ABB

-- Eaton

-- Emerson Electric

-- Eurogroup S.P.A

-- General Electric

-- Honeywell

-- Hyundai Rotem Co

-- Lake Air Companies

-- Lamination Specialties Incorporated

-- LCS Company

-- Littelfuse

-- Mitsubishi Electric

-- Nidec Corporation

-- Parker Hannifin

-- Partzsch Elektromotoren E.K.

-- Pitti Laminations Ltd.

-- Polaris Laser Laminations, LLC.

-- Precision Micro Ltd

-- R. Bourgeois

-- Rockwell Automation

Conclusion

The Motor Lamination Market is poised for substantial growth, propelled by the increasing demand for electric and hybrid vehicles, which are integral to the global shift towards sustainable transportation. This sector is experiencing significant advancements in material technology and manufacturing processes aimed at enhancing motor efficiency and performance. The adoption of high-quality electrical steel used in these laminations is critical in reducing energy losses typical in electric motors, making these innovations crucial for the industry's progress.

Lawrence John

Prudour

+91 91308 55334

Lawrence@prudour.com

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.