Micro injection molding enables high-precision, efficient production of small plastic parts, revolutionizing industries like medical, optics, and electronics.

CHANGHUA, TAIWAN, March 30, 2025 /EINPresswire.com/ -- The world of manufacturing is constantly evolving, with new technologies and techniques emerging to meet the demands of various industries. One such innovation is micro injection molding, a highly precise and efficient method of producing small plastic parts. This process has gained popularity in recent years due to its ability to create intricate and complex designs with tight tolerances. Let's take a closer look at what micro injection molding is and how it is revolutionizing the manufacturing industry.

Micro injection molding is a specialized form of injection molding, a manufacturing process where molten plastic is injected into a mold to create a desired shape. However, in micro injection molding, the molds are much smaller and the parts produced are typically less than one gram in weight. This allows for the production of tiny components with high precision and accuracy. The process involves using a precision injection mold, which is designed to create intricate details and maintain tight tolerances, resulting in consistent and high-quality parts.

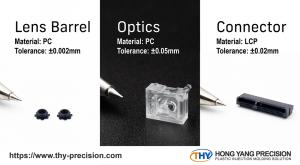

One of the key benefits of micro injection molding is its ability to produce parts with extremely tight injection molding tolerances. This means that the final product will have minimal variation in size and shape, ensuring a perfect fit and function. This is especially important in industries such as medical and electronics, where precision is crucial. Additionally, micro injection molding is a highly efficient process, with the ability to produce large quantities of parts in a short amount of time. This makes it a cost-effective solution for businesses looking to mass-produce small components.

As the demand for smaller and more intricate parts continues to grow, the use of micro injection molding is expected to increase. This technology has already made a significant impact in various industries, including medical, optics, and electronics. With its precision and efficiency, micro injection molding is set to revolutionize the manufacturing industry and open up new possibilities for product design and development.

In conclusion, micro injection molding is a game-changing technology that offers precision, efficiency, and cost-effectiveness. Its ability to produce small plastic parts with tight tolerances has made it a popular choice for various industries. As the manufacturing landscape continues to evolve, micro injection molding is poised to play a significant role in meeting the demands of the future.

About Hong Yang Precision Industry Co., Ltd. (THY Precision)

THY Precision is a leading OEM plastic injection molding contract manufacturer with over 40 years of experience in custom plastic injection molding. They specialize in high-precision tooling, medical device injection molding, optical injection molding, micro injection molding, cleanroom injection molding, cleanroom assembly, and cleanroom packaging. Their precision plastic injection molding services cater to industries such as medical devices, optics, and electronics manufacturing. Partner with Hong Yang Precision (THY Precision) for high-quality, ISO 13485 & ISO 9001 -certified plastic injection molding solutions tailored to your industry needs. Please visit https://www.thy-precision.com for further information.

Sharon Kao

Hong Yang Precision Industry Co., Ltd.

sales@thy-precision.com

Visit us on social media:

Facebook

X

LinkedIn

YouTube

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.