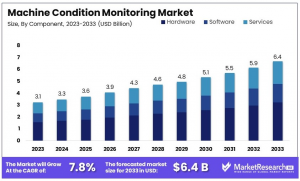

Global Machine Condition Monitoring Market to Reach USD 6.4 Billion by 2033, Growing at a CAGR of 7.8% from USD 3.1 Billion in 2023

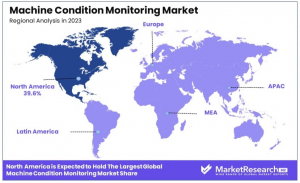

North America holds 39.6% of the machine condition monitoring market, driven by advanced industrial infrastructure and a focus on operational efficiency.”

NEW YORK, NY, UNITED STATES, January 31, 2025 /EINPresswire.com/ -- Market Overview— Tajammul Pangarkar

The Global Machine Condition Monitoring Market size is expected to be worth around USD 6.4 Billion by 2033, from USD 3.1 Billion in 2023, growing at a CAGR of 7.8% during the forecast period from 2024 to 2033.

The Machine Condition Monitoring Market refers to the industry focused on technologies and solutions that monitor the health and performance of machinery and equipment in real-time. These systems help predict potential failures, reduce downtime, and optimize maintenance schedules, ensuring operational efficiency across industries such as manufacturing, energy, automotive, and aerospace. By leveraging sensors, software, and data analytics, machine condition monitoring enables businesses to transition from reactive to proactive maintenance strategies.

The Machine Condition Monitoring Market is poised for significant growth, driven by the increasing adoption of predictive maintenance strategies and the rise of Industry 4.0. As industries prioritize operational efficiency and cost reduction, the demand for advanced monitoring solutions is escalating. Governments worldwide are also playing a pivotal role by investing in smart manufacturing initiatives and infrastructure modernization.

For instance, policies promoting industrial automation and energy efficiency are creating a favorable environment for market expansion. Additionally, stringent regulations related to workplace safety and equipment reliability are compelling organizations to adopt machine condition monitoring systems. These factors, combined with the growing emphasis on sustainability, are expected to fuel market growth over the coming years.

The Machine Condition Monitoring Market presents substantial opportunities for both new entrants and established players. For new companies, the market offers a chance to innovate with cost-effective, scalable, and user-friendly solutions tailored to small and medium-sized enterprises (SMEs).

Existing players can capitalize on their expertise to expand their product portfolios, integrate advanced technologies like AI and IoT, and explore untapped industries such as agriculture and healthcare. Strategic partnerships, mergers, and acquisitions can further enhance market presence and drive business growth. By addressing the evolving needs of industries and leveraging technological advancements, companies can position themselves as leaders in this dynamic and competitive market.

Curious About Market Trends? Request Your Complimentary Sample Report Today: https://marketresearch.biz/report/machine-condition-monitoring-market/request-sample/

Key Takeaway

-- Market Value: The Global Machine Condition Monitoring Market is expected to be worth USD 6.4 billion by 2033, from USD 3.1 billion in 2023, with a CAGR of 7.8%.

--Component Analysis: Hardware dominates with 50%; essential for real-time data capture.

--Monitoring Technique Analysis: Vibration monitoring dominates with 40%; effective for detecting mechanical faults.

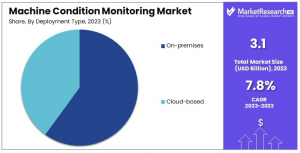

--Deployment Type Analysis: On-premises deployment dominates with 60%; need for data control and integration.

--End User Industry Analysis: Manufacturing dominates with 35%; high demand for equipment reliability.

--Dominant Region: North America with 39.6%; advanced industrial infrastructure.

Use Cases

Manufacturing Industry: In manufacturing plants, machine condition monitoring systems are used to track the health of machinery and equipment. By detecting issues like vibrations, temperature changes, and wear and tear, these systems help prevent unexpected breakdowns, reduce downtime, and maintain production efficiency.

Energy Sector: Power plants, including those using wind, solar, and fossil fuels, rely on machine condition monitoring to ensure the reliability and efficiency of their equipment. Early detection of faults in turbines, generators, and other critical machinery helps avoid costly repairs and power outages.

Oil and Gas Industry: In the oil and gas sector, machine condition monitoring is crucial for maintaining the integrity of drilling rigs, pipelines, and refineries. By monitoring parameters like pressure, temperature, and vibration, these systems help prevent leaks, spills, and equipment failures, ensuring safe and efficient operations.

Transportation and Logistics: The transportation industry uses machine condition monitoring to maintain the health of vehicles, trains, and aircraft. By tracking engine performance, brake conditions, and other critical parameters, these systems help ensure the safety and reliability of transportation networks.

Mining Industry: In mining operations, machine condition monitoring is used to keep heavy machinery like excavators, conveyors, and crushers in optimal condition. By detecting early signs of wear and potential failures, these systems help reduce downtime, improve safety, and enhance productivity in challenging mining environments.

Driving Factors

Industry 4.0 Adoption: The push toward smart factories is making condition monitoring essential. Companies are investing in sensors and monitoring systems to predict equipment failures and optimize maintenance schedules. This digital transformation is moving from nice-to-have to must-have status across manufacturing.

Cost Reduction Pressure: Unexpected machine breakdowns can cost millions in lost production. Businesses are finding that investing in monitoring systems is cheaper than dealing with emergency repairs and production stops. The clear ROI makes it easier for companies to justify the investment.

Skilled Labor Shortage: With experienced maintenance workers becoming harder to find, companies are turning to automated monitoring systems. These systems help less experienced staff make better maintenance decisions by providing clear data and early warnings of problems.

Wireless Sensor Technology: Advances in wireless sensors have made monitoring more practical and less expensive. Companies can now install sensors without major infrastructure changes, making it easier to start monitoring programs and expand them gradually.

Data Analytics Integration: The combination of monitoring systems with advanced analytics is providing deeper insights. Companies can now not only detect problems but also understand patterns and optimize their entire operation, driving demand for more sophisticated systems.

Report Segmentation

By Component

• Hardware

• Software

• Services

By Monitoring Technique

• Vibration Monitoring

• Ultrasound Monitoring

• Thermography

• Oil Analysis

• Motor Current Analysis

• Others

By Deployment Type

• On-premises

• Cloud-based

By End User Industry

• Manufacturing

• Oil and Gas

• Power Generation

• Aerospace and Defense

• Automotive

• Chemical and Petrochemical

• Mining and Metals

• Food and Beverage

• Others

Ready to Act on Market Opportunities? Buy Your Report Now and Get 30% off: https://marketresearch.biz/purchase-report/?report_id=46775

Regional Analysis

North America holds a dominant share of 39.6% in the machine condition monitoring market, largely due to its advanced industrial infrastructure and commitment to ensuring the operational efficiency of machinery. With industries like manufacturing, oil and gas, mining, and automotive booming in the region, there is an increasing need for predictive maintenance solutions that can help identify potential failures before they lead to costly downtime.

Condition monitoring technologies, which use sensors and IoT systems to track the performance and health of machinery, allow for real-time data collection and analysis. This is essential in maintaining productivity and preventing unplanned disruptions in operations. North America’s strong focus on industrial automation, the integration of AI and machine learning, and the adoption of Industry 4.0 practices are also pushing the demand for condition monitoring tools.

Moreover, companies are keen on reducing maintenance costs and extending equipment life, further promoting the growth of the market. With a combination of stringent regulations around equipment safety and an emphasis on technology-driven maintenance solutions, North America continues to be a leader in the machine condition monitoring market.

Growth Opportunities

Predictive Maintenance: The shift from reactive to predictive maintenance in industries is driving demand for machine condition monitoring systems. Companies can offer advanced monitoring solutions that help predict equipment failures before they occur, reducing downtime and maintenance costs.

Integration with IoT: The integration of IoT with machine condition monitoring systems allows for real-time data collection and analysis. Companies can develop IoT-enabled monitoring solutions that provide actionable insights, improving operational efficiency.

Expansion in Manufacturing Sector: The growing manufacturing sector, especially in emerging markets, presents significant growth opportunities. Companies can target manufacturers with cost-effective and reliable machine condition monitoring solutions.

Focus on Energy Efficiency: There is increasing emphasis on energy efficiency in industrial operations. Machine condition monitoring systems that help optimize energy usage can attract customers looking to reduce their energy costs and environmental impact.

After-Sales Services: Offering comprehensive after-sales services, including installation, training, and ongoing support, can enhance customer satisfaction and loyalty. Companies that provide excellent after-sales services can differentiate themselves in a competitive market.

Key Players

• Emerson Electric Co.

• General Electric Company

• Honeywell International Inc.

• SKF Group

• National Instruments Corporation

• Parker Hannifin Corporation

• Rockwell Automation, Inc.

• Siemens AG

• ABB Ltd.

• Brüel & Kjær Vibro GmbH

• Meggitt PLC

• ALS Limited

• Analog Devices, Inc.

• Fluke Corporation

• Azima DLI Corporation

Not Sure? Request a Sample Report and See How Our Insights Can Drive Your Business: https://marketresearch.biz/report/machine-condition-monitoring-market/request-sample/

Conclusion

In conclusion, the markets analyzed are all experiencing growth driven by evolving consumer preferences, technological advancements, and increasing demand for customized, high-quality products. Key trends, such as the adoption of sustainable practices, integration of smart technologies, and rising disposable incomes, are shaping the competitive landscape. While challenges such as market saturation, price sensitivity, and regional differences persist, opportunities abound for companies to capitalize on niche segments, leverage digital platforms, and innovate to meet the specific needs of their target audiences. As these industries continue to expand, businesses that adapt to changing trends, prioritize customer-centric strategies, and invest in innovation will be well-positioned for long-term success.

Related Report

Third Party Logistics 3pl Market: https://marketresearch.biz/report/third-party-logistics-3pl-market/

Air Springs Market: https://marketresearch.biz/report/air-springs-market/

Fleet Telematics Market: https://marketresearch.biz/report/fleet-telematics-market/

Rig And Oilfield Mats Market: https://marketresearch.biz/report/rig-and-oilfield-mats-market/

Connected Ship Market: https://marketresearch.biz/report/connected-ship-market/

Lawrence John

Prudour

+91 91308 55334

Lawrence@prudour.com

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.