The Grinding Machinery Market focuses on machines used for grinding materials, offering efficiency in various industries.

The Grinding Machinery Market is expanding globally, driven by increasing demand for precision and efficiency across industries, fueling innovation and investment.”

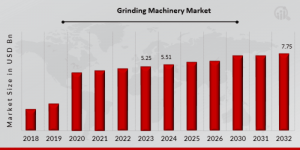

CALIFORNIA, CA, UNITED STATES, March 13, 2025 /EINPresswire.com/ -- Market Research Future published a report titled, The Grinding Machinery Market Size, Share, Competitive Landscape and Trend Analysis Report, by Type, Application, Distribution Channel and Region: Global Opportunity Analysis and Industry Forecast till 2032. The Grinding Machinery market industry is projected to grow from USD 5.51 Billion in 2024 to USD 7.75 Billion by 2032, exhibiting a CAGR of 4.35% during the forecast period 2024 - 2032. Grinding Machinery Market Size was valued at USD 5.25 Billion in 2023.— MRFR

Grinding Machinery Market Comprehensive Analysis and Overview

The grinding machinery market is a crucial segment within the manufacturing industry, playing a significant role in the production processes of various sectors, including automotive, aerospace, electrical and electronics, and metal fabrication.

Grinding machines are used to remove excess material from a workpiece by means of abrasion, ensuring high precision and smooth surface finishes. With the increasing need for high-quality components, the demand for advanced grinding machinery has seen steady growth.

Get Free Sample PDF Brochure: https://www.marketresearchfuture.com/sample_request/3753

Key Companies in the Grinding Machinery market include

Amada Machine Tools Co. Ltd (Japan)

DANOBAT (Spain)

ANCA Pty Ltd (Australia)

Junker (Germany)

Korber AG (Germany)

Fives (France)

Gleason Corporation (US)

Hybrid Manufacturing Technologies (US)

Makino Milling Machine Co. Ltd (Japan)

Market Trends Highlights

The grinding machinery market is currently experiencing dynamic changes driven by technological advancements and evolving customer needs. Some of the key trends include:

Automation and Smart Grinding Machines: The integration of automation and artificial intelligence (AI) in grinding machinery is revolutionizing the industry. Smart grinding machines equipped with sensors and real-time monitoring capabilities enhance productivity, reduce downtime, and ensure consistent quality.

Sustainability and Energy Efficiency: Manufacturers are focusing on developing energy-efficient grinding machines to meet environmental regulations and reduce operational costs. The use of eco-friendly coolants and the adoption of minimal quantity lubrication (MQL) systems are gaining popularity.

Additive Manufacturing Integration: The combination of additive manufacturing and grinding technologies enables the creation of complex geometries with high precision, fostering innovation across industries.

Customization and Modular Designs: Increasing demand for customized grinding machines tailored to specific applications is pushing manufacturers to offer modular and flexible solutions.

Market Dynamics

Understanding the market dynamics is vital to comprehending the growth trajectory of the grinding machinery market. These dynamics include key drivers, restraints, and opportunities shaping the industry’s landscape.

Buy Now Premium Research Report: https://www.marketresearchfuture.com/checkout?currency=one_user-USD&report_id=3753

Market Drivers

Rising Demand for Precision Manufacturing: Industries like aerospace and automotive require high-precision components, driving the need for advanced grinding machines that can deliver tight tolerances and superior surface finishes.

Growth in the Automotive Sector: The automotive industry’s shift toward electric vehicles (EVs) is increasing the demand for precision-engineered parts, propelling the adoption of grinding machinery.

Industrial Automation: The widespread adoption of Industry 4.0 concepts is encouraging manufacturers to invest in automated grinding machines, boosting operational efficiency and reducing labor dependency.

Expanding Metal Fabrication Industry: The growing construction and infrastructure sectors contribute to the rising demand for metal fabrication, which, in turn, supports the grinding machinery market.

Market Restraints

High Initial Investment: Advanced grinding machinery often requires significant capital investment, which may deter small and medium-sized enterprises (SMEs) from adopting these technologies.

Skilled Labor Shortage: The operation and maintenance of sophisticated grinding machines demand skilled personnel, and a shortage of qualified workers poses a challenge for market growth.

Raw Material Price Volatility: Fluctuations in the prices of raw materials used in machine manufacturing can impact production costs and profit margins.

Market Segmentation

The grinding machinery market can be segmented based on product type, application, and geography.

By Product Type:

Surface Grinding Machines: Widely used for producing smooth finishes and flat surfaces.

Cylindrical Grinding Machines: Essential for precision grinding of cylindrical surfaces.

Centerless Grinding Machines: Suitable for mass production and high-precision machining.

Internal Grinding Machines: Used for machining the inner diameter of workpieces.

Specialized Grinding Machines: Custom-designed for specific applications and industries.

By Application:

Automotive: Manufacturing of engine components, gears, and transmission parts.

Aerospace: Production of high-precision turbine blades and aircraft components.

Electrical and Electronics: Grinding of electronic components for circuit boards and semiconductors.

Metal Fabrication: Shaping and finishing metal products for construction and industrial use.

Others: Including medical devices, defense, and heavy machinery.

By Geography:

North America: Driven by technological advancements and strong industrial infrastructure.

Europe: Home to prominent automotive and aerospace industries, fostering demand for precision grinding machinery.

Asia-Pacific (APAC): Rapid industrialization and growth in manufacturing sectors, especially in China, Japan, and India.

Middle East & Africa: Expanding construction activities and infrastructure development.

Latin America: Increasing adoption of automation in manufacturing industries.

Browse In-depth Market Research Report: https://www.marketresearchfuture.com/reports/grinding-machinery-market-3753

Future Trends

The grinding machinery market is poised for significant growth, with several future trends shaping its trajectory:

Adoption of Artificial Intelligence and IoT: AI-driven predictive maintenance and IoT-enabled machines will enhance productivity by minimizing unplanned downtimes and improving overall equipment efficiency.

Sustainable Manufacturing Practices: Green grinding technologies, such as dry grinding and the use of bio-based coolants, will become more prevalent as companies aim to reduce their carbon footprint.

Integration with 3D Printing: Combining grinding machines with additive manufacturing processes will allow for the production of highly complex components with superior accuracy.

Enhanced Human-Machine Interfaces (HMIs): User-friendly interfaces and touchscreen controls will simplify machine operation, reducing the need for extensive training.

Expansion of Customization Options: Manufacturers will focus on offering flexible grinding solutions tailored to specific customer needs, enhancing product differentiation.

The grinding machinery market is on an upward trajectory, driven by technological innovations, rising demand for precision engineering, and the growing adoption of automated solutions. While challenges such as high initial costs and skilled labor shortages remain, the industry's future looks promising with the integration of AI, IoT, and sustainable practices. As manufacturing processes continue to evolve, the grinding machinery market is set to play a pivotal role in shaping the future of precision engineering.

More Related Reports:

Smart Air Purifier Market: https://www.marketresearchfuture.com/reports/smart-air-purifier-market-6895

CNC Metal Cutting Machine Tools Market: https://www.marketresearchfuture.com/reports/cnc-metal-cutting-machine-tools-market-7201

Steel Wind Tower Market: https://www.marketresearchfuture.com/reports/steel-wind-tower-market-7337

CNC Polishing Machines Market : https://www.marketresearchfuture.com/reports/cnc-polishing-machines-market-7571

Triangle Tea Bag Packaging Machinery Market: https://www.marketresearchfuture.com/reports/triangle-tea-bag-packaging-machinery-market-7672

𝐀𝐛𝐨𝐮𝐭 𝐌𝐚𝐫𝐤𝐞𝐭 𝐑𝐞𝐬𝐞𝐚𝐫𝐜𝐡 𝐅𝐮𝐭𝐮𝐫𝐞

At Market Research Future (MRFR), we enable our customers to unravel the complexity of various industries through our Cooked Research Report (CRR), Half-Cooked Research Reports (HCRR), Raw Research Reports (3R), Continuous-Feed Research (CFR), and Market Research Consulting Services. The MRFR team have a supreme objective to provide the optimum quality market research and intelligence services for our clients. Our market research studies by Components, Application, Logistics and market players for global, regional, and country level market segments enable our clients to see more, know more, and do more, which help to answer all their most important questions.

Market Research Future

Market Research Future

+1 855-661-4441

email us here

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.