Europe Advanced Aerospace Coatings market grows with demand for UV-resistant, high-temp coatings in hypersonic and stratospheric aerospace systems.

The shift toward hypersonic vehicles and stratospheric drones is redefining Europe’s aerospace coatings market, with innovation focused on UV, heat, and REACH-compliant solutions.”

NEWARK, DE, UNITED STATES, June 3, 2025 /EINPresswire.com/ -- The Europe Advanced Aerospace Coatings market is often evaluated through metrics such as corrosion resistance, weight optimization, and compliance with REACH environmental standards. While these are undoubtedly essential, a rarely explored yet rapidly emerging segment is the development and deployment of high-altitude, UV-resistant coatings designed for hypersonic vehicles and stratospheric unmanned aerial systems (UAS). As Europe accelerates its presence in high-speed and high-altitude flight technologies, coatings are becoming not just protective surfaces—but enablers of performance, survivability, and mission success.— Nikhil Kaitwade, Associate Vice President at Future Market Insights

Driven by advancements in the defense sector, climate research platforms, and satellite-alternative systems, the Europe Advanced Aerospace Coatings market is witnessing strategic investments in next-generation coatings that can withstand extreme ultraviolet radiation, low-pressure environments, and supersonic thermal fluctuations—conditions rarely encountered by traditional commercial aircraft.

𝐌𝐚𝐤𝐞 𝐈𝐧𝐟𝐨𝐫𝐦𝐞𝐝 𝐃𝐞𝐜𝐢𝐬𝐢𝐨𝐧𝐬 – 𝐀𝐜𝐜𝐞𝐬𝐬 𝐘𝐨𝐮𝐫 𝐒𝐚𝐦𝐩𝐥𝐞 𝐑𝐞𝐩𝐨𝐫𝐭 𝐈𝐧𝐬𝐭𝐚𝐧𝐭𝐥𝐲! https://www.futuremarketinsights.com/reports/sample/rep-eu-82

𝐄𝐮𝐫𝐨𝐩𝐞’𝐬 𝐇𝐲𝐩𝐞𝐫𝐬𝐨𝐧𝐢𝐜 𝐚𝐧𝐝 𝐒𝐭𝐫𝐚𝐭𝐨𝐬𝐩𝐡𝐞𝐫𝐢𝐜 𝐌𝐨𝐦𝐞𝐧𝐭𝐮𝐦

While North America and China lead many aspects of hypersonic weapon and high-altitude reconnaissance system development, Europe is quietly establishing its own capabilities. Projects such as HEXAFLY-INT, coordinated by the European Space Agency and several EU research bodies, are building experimental hypersonic demonstrators aimed at achieving flight speeds over Mach 5. In parallel, aerospace startups in Germany, the Netherlands, and France are deploying stratospheric balloons and drones for long-duration Earth observation, communications, and atmospheric research.

Operating at altitudes of 20–50 kilometers, these systems are exposed to solar radiation levels over 10 times greater than those at sea level. Temperatures can swing from +100°C on sunlit surfaces to -80°C in shadow, demanding a new class of surface coatings. This demand is opening new avenues for product development and R&D in the Europe Advanced Aerospace Coatings market, with a focus on UV resistance, emissivity control, and structural durability under fluctuating thermal loads.

𝐂𝐡𝐚𝐥𝐥𝐞𝐧𝐠𝐞𝐬 𝐨𝐟 𝐂𝐨𝐚𝐭𝐢𝐧𝐠 𝐟𝐨𝐫 𝐇𝐢𝐠𝐡-𝐀𝐥𝐭𝐢𝐭𝐮𝐝𝐞 𝐚𝐧𝐝 𝐇𝐲𝐩𝐞𝐫𝐬𝐨𝐧𝐢𝐜 𝐀𝐩𝐩𝐥𝐢𝐜𝐚𝐭𝐢𝐨𝐧𝐬

Conventional aerospace coatings, typically polyurethane-based coatings, are effective at providing corrosion resistance and minor thermal protection. However, they degrade under extended exposure to extreme UV-A and UV-B radiation, as well as atomic oxygen present at the edge of space. Moreover, at hypersonic speeds, vehicle surfaces can reach 1,000–2,000°C, especially around leading edges and engine nacelles.

This necessitates specialized coatings that integrate ceramic matrix composites, high-temperature pigments, and thermally emissive layers. These formulations are critical innovations in the Europe Advanced Aerospace Coatings market, applied using advanced processes such as plasma spraying or electron beam physical vapor deposition (EB-PVD).

In 2024, a collaborative trial led by Germany’s DLR (German Aerospace Center) and the University of Stuttgart tested solar-reflective thermal barrier coatings on high-speed drone prototypes. These coatings reduced surface degradation by over 45% compared to legacy systems, highlighting the role of high-performance surface materials in shaping the future of European aerospace.

𝐔𝐧𝐥𝐨𝐜𝐤 𝐂𝐨𝐦𝐩𝐫𝐞𝐡𝐞𝐧𝐬𝐢𝐯𝐞 𝐌𝐚𝐫𝐤𝐞𝐭 𝐈𝐧𝐬𝐢𝐠𝐡𝐭𝐬 – 𝐄𝐱𝐩𝐥𝐨𝐫𝐞 𝐭𝐡𝐞 𝐅𝐮𝐥𝐥 𝐑𝐞𝐩𝐨𝐫𝐭 𝐍𝐨𝐰: https://www.futuremarketinsights.com/reports/europe-advanced-aerospace-coatings-market

𝐌𝐚𝐭𝐞𝐫𝐢𝐚𝐥𝐬 𝐈𝐧𝐧𝐨𝐯𝐚𝐭𝐢𝐨𝐧 𝐚𝐧𝐝 𝐄𝐧𝐯𝐢𝐫𝐨𝐧𝐦𝐞𝐧𝐭𝐚𝐥 𝐂𝐨𝐦𝐩𝐥𝐢𝐚𝐧𝐜𝐞: 𝐀 𝐃𝐮𝐚𝐥 𝐈𝐦𝐩𝐞𝐫𝐚𝐭𝐢𝐯𝐞

Another uniquely European challenge is the need to reconcile military-grade performance requirements with strict environmental regulations, particularly under REACH. Chromate-based coatings—once standard for aerospace anti-corrosion applications—are now being phased out, pushing researchers to develop non-toxic substitutes that still meet aerospace durability benchmarks.

This regulatory pressure has spurred innovation across the Europe Advanced Aerospace Coatings market. For instance, chromate-free primers infused with graphene nanoparticles are being explored for their superior conductivity and corrosion resistance. Companies like Mapaero in France (now part of AkzoNobel Aerospace Coatings) are spearheading such sustainable coating technologies.

In parallel, nanocoatings using tungsten disulfide (WS₂) and boron nitride are under trial for their low-friction, high-durability performance—an area where the Europe Advanced Aerospace Coatings market can lead through functional material science innovation.

𝐓𝐡𝐞 𝐂𝐨𝐦𝐩𝐞𝐭𝐢𝐭𝐢𝐯𝐞 𝐋𝐚𝐧𝐝𝐬𝐜𝐚𝐩𝐞: 𝐍𝐢𝐜𝐡𝐞 𝐏𝐥𝐚𝐲𝐞𝐫𝐬 𝐋𝐞𝐚𝐝𝐢𝐧𝐠 𝐈𝐧𝐧𝐨𝐯𝐚𝐭𝐢𝐨𝐧

Unlike the U.S., where aerospace coating innovation is dominated by large defense contractors, the Europe Advanced Aerospace Coatings market is shaped by a distributed ecosystem of university labs, SMEs, and government-backed research centers. This model supports collaborative innovation and faster translation of scientific advances into prototype applications.

For example, the AEROCOAT EU project, launched in 2023, is focused on developing self-healing coatings for high-altitude drones. Participants include Spain’s CIDETEC, Germany’s Fraunhofer IFAM, and multiple SMEs. These coatings can repair micro-cracks autonomously—an innovation that would enhance the durability of platforms operating in extreme environments.

This approach allows the Europe Advanced Aerospace Coatings market to maintain a technological edge in performance coatings, even if production volumes remain lower compared to global counterparts.

𝐌𝐚𝐫𝐤𝐞𝐭 𝐎𝐮𝐭𝐥𝐨𝐨𝐤: 𝐀 𝐍𝐢𝐜𝐡𝐞 𝐏𝐨𝐢𝐬𝐞𝐝 𝐟𝐨𝐫 𝐆𝐫𝐨𝐰𝐭𝐡

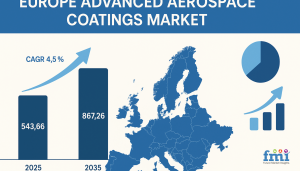

According to Future Market Insights, the European Advanced Aerospace Coatings market is estimated to reach USD 543.66 million in 2025. A CAGR of 4.5% is expected through 2035. By 2035, the market value is forecasted to hit USD 867.26 million.

This growth is being driven not only by defense modernization programs but also by increased interest in stratospheric drones for Earth observation and climate monitoring. As Europe continues to embrace dual-use aerospace technologies, coatings that enhance both environmental performance and platform resilience will become increasingly central.

𝐂𝐨𝐚𝐭𝐢𝐧𝐠𝐬, 𝐈𝐧𝐤𝐬, 𝐀𝐝𝐡𝐞𝐬𝐢𝐯𝐞𝐬 & 𝐒𝐞𝐚𝐥𝐚𝐧𝐭𝐬 𝐈𝐧𝐝𝐮𝐬𝐭𝐫𝐲 𝐀𝐧𝐚𝐥𝐲𝐬𝐢𝐬: https://www.futuremarketinsights.com/industry-analysis/coatings-inks-adhesives-and-sealants

𝐂𝐨𝐚𝐭𝐢𝐧𝐠𝐬 𝐚𝐬 𝐂𝐫𝐢𝐭𝐢𝐜𝐚𝐥 𝐄𝐧𝐚𝐛𝐥𝐞𝐫𝐬 𝐨𝐟 𝐀𝐥𝐭𝐢𝐭𝐮𝐝𝐞 𝐚𝐧𝐝 𝐒𝐩𝐞𝐞𝐝

The Europe Advanced Aerospace Coatings market is entering a new phase where surface technology is not just passive protection—but a strategic performance differentiator. From enabling reusable hypersonic testbeds to protecting stratospheric drones against solar radiation and oxidation, next-generation coatings are critical to Europe’s aerospace ambitions.

As regulatory compliance and environmental sustainability converge with the need for high-temperature, high-durability materials, the Europe Advanced Aerospace Coatings market will remain a focal point for both innovation and strategic investment. This niche, though currently understated, represents one of the most science-intensive and forward-looking frontiers in the global aerospace value chain.

𝐈𝐧𝐝𝐮𝐬𝐭𝐫𝐲 𝐒𝐞𝐠𝐦𝐞𝐧𝐭 𝐨𝐟 𝐀𝐝𝐯𝐚𝐧𝐜𝐞𝐝 𝐀𝐞𝐫𝐨𝐬𝐩𝐚𝐜𝐞 𝐂𝐨𝐚𝐭𝐢𝐧𝐠 𝐢𝐧 𝐄𝐮𝐫𝐨𝐩𝐞

By Product Type:

- Primer

- Epoxy

- Polyurethane

- Others

- Topcoat

- Epoxy

- Polyurethane

- Others

- Solvent

- Ceramic Coatings

By Application:

- Interior

- Exterior

By End Use:

- Commercial

- General & Business

- Military

By Country:

- Germany

- UK

- France

- Spain

- Italy

- Rest of Europe

𝐑𝐞𝐥𝐚𝐭𝐞𝐝 𝐑𝐞𝐩𝐨𝐫𝐭𝐬:

Perfluoropolyether (PFPE) Market: https://www.futuremarketinsights.com/reports/perfluoropolyether-market

Carbon Mold Market: https://www.futuremarketinsights.com/reports/carbon-mold-market

Automotive Bioplastic Market: https://www.futuremarketinsights.com/reports/automotive-bioplastic-market

Lithium and Lithium Ion Battery Electrolytes Market: https://www.futuremarketinsights.com/reports/lithium-and-lithium-ion-battery-electrolytes-market

Vulcanization Accelerators Market: https://www.futuremarketinsights.com/reports/vulcanization-accelerators-market

𝐀𝐛𝐨𝐮𝐭 𝐅𝐮𝐭𝐮𝐫𝐞 𝐌𝐚𝐫𝐤𝐞𝐭 𝐈𝐧𝐬𝐢𝐠𝐡𝐭𝐬 (𝐅𝐌𝐈)

Future Market Insights, Inc. (ESOMAR certified, recipient of the Stevie Award, and a member of the Greater New York Chamber of Commerce) offers profound insights into the driving factors that are boosting demand in the market. FMI stands as the leading global provider of market intelligence, advisory services, consulting, and events for the Packaging, Food and Beverage, Consumer Technology, Healthcare, Industrial, and Chemicals markets. With a vast team of over 400 analysts worldwide, FMI provides global, regional, and local expertise on diverse domains and industry trends across more than 110 countries.

Join us as we commemorate 10 years of delivering trusted market insights. Reflecting on a decade of achievements, we continue to lead with integrity, innovation, and expertise.

𝐂𝐨𝐧𝐭𝐚𝐜𝐭 𝐔𝐬:

Future Market Insights Inc.

Christiana Corporate, 200 Continental Drive,

Suite 401, Newark, Delaware - 19713, USA

T: +1-347-918-3531

For Sales Enquiries: sales@futuremarketinsights.com

Website: https://www.futuremarketinsights.com

LinkedIn| Twitter| Blogs | YouTube

Ankush Nikam

Future Market Insights Global & Consulting Pvt. Ltd.

+ +91 90966 84197

email us here

Visit us on social media:

Other

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.