MDF and Chipboard Market to Reach $134.5 Billion

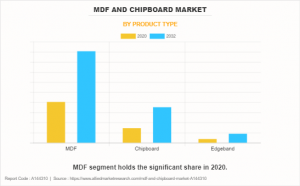

WILMINGTON, DELAWARE, UNITED STATES, January 19, 2024 /EINPresswire.com/ -- The 2020 global market size for Medium Density Fiberboard (MDF) and chipboard amounted to $58.6 billion, with a projected growth to $134.5 billion by 2032. This represents a Compound Annual Growth Rate (CAGR) of 6.2% from 2023 to 2032. Medium Density Fiberboard, commonly known as MDF, is an engineered wood product created by combining wood fibers, often derived from softwood or hardwood residuals, with synthetic resins and adhesives under high temperatures and pressure. Chipboard, also known as particleboard, is another engineered wood composite formed by blending wood particles, chips, or flakes with a binding adhesive, using heat and pressure. Both MDF and chipboard serve as cost-effective alternatives to solid wood, catering to the demand for sustainable material utilization.

Download Sample Copy: https://www.alliedmarketresearch.com/request-sample/144794

Medium-density fiberboards and chipboards are some of the most extensively used materials in the construction and furniture sector. While they bear close resemblance in terms of usage and composition, there is a significant difference between these two materials.

Major differences between MDF and Chipboard

First and foremost, MDF and chipboards vary in their composition. Chipboards are primarily made from wood chips, saw dust, and similar other wood particles. These particles are compressed by applying high pressure and heat to it. Thus, though artificially made, chipboards are composed of natural raw materials. On the other hand, MDF has 90-95% natural raw materials. MDF is made from wood fibers which are bound together using synthetic resins. This mixture then undergoes the same process as that of chipboards.

Buy This Report: https://www.alliedmarketresearch.com/checkout-final/4d47ff871c3cd6fe2bda2143a1104452

Another major difference between the two is with respect to durability and strength. Since MDF has a more uniform composition, it has greater strength as compared to chipboards and is more durable in nature. Also, since MDF has some artificial raw materials in it, the moisture resistance of MDF is much more as compared to chipboards. Since chipboards are more susceptible to impacts, furniture made using chipboards cannot be reassembled. However, chipboards have a higher screw holding capacity and hence are used in applications which involve inserting screws or nails. The wide applicability of MDF boards has resulted in various color options being launched in the market; chipboards have limited color options in the market.

There is also a huge difference with respect to the cost of these two materials. MDF is quite expensive as compared to chipboards due to its obvious advantages. Due to these factors, MDF is generally used for making furniture that will be used for a longer time span, while chipboards are used to make items which serve a rather temporary purpose. Over the years, with the growing pace of urbanization and expansion of residential construction sector, the demand for both MDF and chipboards has increased significantly.

Inquire Before Buying: https://www.alliedmarketresearch.com/purchase-enquiry/144794

By Application

Cabinet

Flooring

Furniture

Molding, Door, and Millwork

Packaging System

Others

By End User Industry

Residential

Commercial

Institutional

By Product Type

Standard MDF

Moisture Resistant MDF

Fire Resistant MDF

Chipboard

Edgeband

David Correa

Allied Analytics LLP

+ + +1 800-792-5285

email us here

Visit us on social media:

Facebook

Twitter

LinkedIn