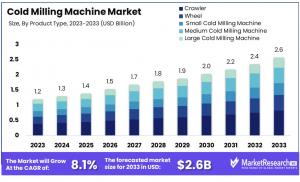

The cold milling machine market, valued at USD 1.2 billion in 2023, is projected to reach USD 2.6 billion by 2033, growing at a CAGR of 8.11%.

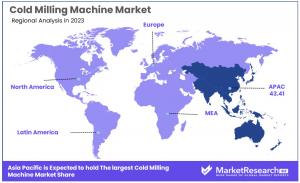

Asia-Pacific leads the cold milling machine market with a 43.41% share, driving The Market growth from USD 1.2 billion in 2023 to an expected USD 2.6 billion by 2033.”

NEW YORK, NY, UNITED STATES, January 22, 2025 /EINPresswire.com/ -- Report Overview— Tajammul Pangarkar

The Cold Milling Machine Market was valued at USD 1.2 billion in 2023 and is projected to reach USD 2.6 billion by 2033, growing at a CAGR of 8.11% from 2024 to 2033.

A cold milling machine is a heavy-duty construction equipment primarily used in road maintenance and resurfacing. It works by removing the upper layer of asphalt or concrete from roadways, bridges, and other surfaces, without the need for heating. The process involves a rotating drum with sharp, carbide-tipped teeth that grind and mill the surface, leaving a smooth and even base for resurfacing or repaving. This technology is critical for maintaining road integrity, as it not only aids in resurfacing but also in recycling materials for reuse.

The cold milling machine market refers to the global industry surrounding the manufacturing, distribution, and use of these machines in construction, road maintenance, and civil engineering. The market encompasses various types of cold milling machines, such as small, medium, and large-sized machines, designed to cater to different applications ranging from small urban projects to large-scale highway renovations. As infrastructure development continues to grow globally, the demand for efficient road milling equipment has been on the rise.

Several key factors are driving the growth of the cold milling machine market. These include the increasing need for road repairs and maintenance, urbanization, and the growing focus on sustainability, where cold milling machines allow for the recycling of old pavement materials. Additionally, technological advancements in machinery, such as improved precision and automation, have led to greater efficiency and cost-effectiveness.

Opportunities in the market lie in the expanding construction sectors of emerging economies, where urban infrastructure development is booming. Furthermore, innovations in equipment design and the increasing adoption of rental models present avenues for growth within the market.

Download Your Sample Report and Explore Key Insights Today at https://marketresearch.biz/report/cold-milling-machine-market/request-sample/

Key Takeaways

~~ The cold milling machine market is projected to grow from USD 1.2 billion in 2023 to USD 2.6 billion by 2033, at a CAGR of 8.11% from 2024 to 2033, driven by the surge in infrastructure development and road construction activities.

~~ Crawler cold milling machines dominate the market due to their superior stability and performance on uneven surfaces, capturing the largest share in this segment.

~~ Cold milling machines with milling widths below 2ft lead the market, being highly versatile and widely used for surface repairs and minor corrections.

~~ The medium engine power category dominates, offering a balance of efficiency and capability for diverse milling operations.

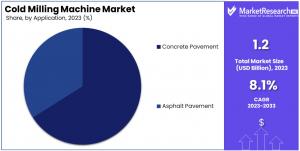

~~ Asphalt pavement milling holds a significant share due to its critical role in road resurfacing and maintenance projects, making it the most prominent application.

~~ Asia-Pacific holds the largest market share (43.41%) due to its rapid infrastructure development and road construction in emerging economies like China and India.

Regional Analysis

Asia Pacific Cold Milling Machine Market with Largest Market Share (43.41%)

The Cold Milling Machine market is led by the Asia Pacific region, accounting for 43.41% of the global share in 2023. This dominance is driven by rapid urbanization, significant infrastructure development, and a high demand for road maintenance, particularly in countries like China, India, and Japan. Government initiatives and a push for sustainable construction solutions are further accelerating market growth in this region.

North America ranks second, supported by technological advancements and infrastructure renewal in the U.S. and Canada. Europe is also witnessing strong demand, particularly in Germany, the UK, and France, where road efficiency and environmental concerns are key drivers. The Middle East & Africa region is growing due to infrastructure projects in the GCC countries, while Latin America, led by Brazil and Mexico, remains an emerging market.

Market Segmentation Analysis

By Type

Crawler Cold Milling Machines dominate the market due to their superior stability, traction, and performance on uneven surfaces, making them ideal for large-scale operations. While Crawler machines lead, Wheel Cold Milling Machines are also significant, offering mobility and speed for quick relocations, particularly in urban settings. Additionally, Small, Medium, and Large Cold Milling Machines cater to various project sizes, from minor surface corrections to major road rehabilitation, with each type offering specific advantages based on the scale and requirements of the operation.

By Milling Width

Cold milling machines with milling widths below 2ft dominate the market due to their versatility for surface repairs, minor corrections, and edge work in both urban and rural areas. These compact machines are ideal for confined spaces. However, machines with widths between 2ft - 5ft and above 5ft are also important, serving larger-scale operations like major roadworks and large surface milling tasks, offering greater efficiency and speed.

By Engine Power:

Cold milling machines are segmented by engine power into Low, Medium, and High categories. Low-power machines suit smaller, less demanding projects, while medium and high-power machines are needed for larger, more challenging milling operations. The choice depends on factors like milling depth, material hardness, and project scale.

By Application:

Cold milling machines are essential for both concrete and asphalt pavement milling. Concrete milling is used for extracting surfaces for reuse in rehabilitation, while asphalt milling removes layers for road resurfacing in maintenance projects. These machines are crucial for efficient pavement removal in road construction and maintenance.

Cold Milling Machine Industry Segments

By Type

~~ Crawler

~~ Wheel

~~ Small Cold Milling Machine

~~ Medium Cold Milling Machine

~~ Large Cold Milling Machine

By Milling Width:

~~ Below 2ft

~~ 2ft - 5ft

~~ Above 5ft

By Engine Power:

~~ Low

~~ Medium

~~ High

By Application:

~~ Concrete Pavement

~~ Asphalt Pavement

Purchase Your Detailed Report Today and Save Up to 30% at https://marketresearch.biz/purchase-report/?report_id=43151

Driving factors

Technological Advancements in Cold Milling Machines

The ongoing advancements in cold milling machine technology have become a major driver for the market's growth. Over the past few years, manufacturers have focused on improving the performance, efficiency, and precision of milling machines, which in turn has positively impacted their demand. Features such as automated control systems, advanced sensor technology, and enhanced fuel efficiency are not only making cold milling machines more user-friendly but also more productive in reducing downtime. Additionally, the integration of data analytics allows for predictive maintenance, which increases the lifespan and operational efficiency of the machines.

Restraining Factors

High Initial Investment and Maintenance Costs

The high initial cost of cold milling machines remains one of the significant restraints hindering market growth. Although these machines offer long-term cost savings through efficiency and reduced labor requirements, their upfront investment can be prohibitive, particularly for small and medium-sized enterprises (SMEs) or those in emerging markets. The price of advanced models equipped with the latest technological features can exceed millions of dollars, limiting accessibility for businesses with tighter budgets.

Growth Opportunity

Growing Demand for Road Infrastructure Development

A key opportunity for the cold milling machine market lies in the rapid global expansion of road infrastructure development, particularly in emerging economies. The construction of new highways, bridges, and tunnels is on the rise, driving the need for more efficient road rehabilitation and surface preparation. Cold milling machines play a critical role in these projects by enabling precise and cost-effective road resurfacing, eliminating the need for traditional methods that are both time-consuming and labor-intensive.

Latest Trends

Integration of Automation and Smart Technologies

The integration of automation and smart technologies is emerging as a defining trend in the cold milling machine market. With increasing demand for higher productivity and cost efficiency, manufacturers are embedding cutting-edge technologies into their machines. Features such as GPS-based systems, remote monitoring, and autonomous milling capabilities are transforming how cold milling machines are operated. These smart technologies enable operators to manage machines more efficiently, optimize milling processes, and track the machine’s performance in real time.

Get a Preview or Tailored Analysis Before Finalizing Your Purchase.

Key Players Analysis

In 2024, the global cold milling machine market is highly competitive, with key players leveraging innovation and regional expansion to strengthen their positions. DEERE & COMPANY (Wirtgen Group), a market leader, continues to benefit from its strong product portfolio, advanced technology integration, and established presence in North America and Europe. Caterpillar Inc., with its robust manufacturing capabilities and customer-focused solutions, remains a dominant player, driving growth through a comprehensive range of high-performance cold milling machines. Astec Industries Inc. and SANY Group have made significant strides by introducing cost-effective, high-quality machines, targeting emerging markets with favorable growth potential.

Fayat Group (Bomag GmbH), CMI Roadbuilding Limited, and Sakai Heavy Industries Limited continue to innovate with an emphasis on reducing fuel consumption and increasing efficiency. Komatsu Ltd., CNH Industrial NV, and Kubota Corporation are capitalizing on automation and digital technologies to deliver next-gen solutions, while Simex srl, Volvo Construction Equipment, Liugong Machinery Co., Ltd., and J C Bamford Excavators Ltd focus on enhancing machine versatility and sustainability features to meet diverse customer needs. These companies’ sustained focus on technological advancements and strategic partnerships will play a pivotal role in shaping market dynamics through 2024.

Cold Milling Machine Market Key Players

~~ DEERE & COMPANY (Wirtgen Group)

~~ Caterpillar Inc.

~~ Astec Industries Inc.

~~ SANY Group

~~ Fayat Group (Bomag GmbH)

~~ CMI Roadbuilding Limited

~~ Sakai Heavy Industries Limited

~~ Komatsu Ltd.

~~ CNH Industrial NV

~~ Simex srl

~~ Kubota Corporation

~~ Volvo Construction Equipment

~~ Liugong Machinery Co., Ltd.

~~ J C Bamford Excavators Ltd

Conclusion

The cold milling machine market is poised for significant growth, driven by the increasing demand for infrastructure development, road maintenance, and resurfacing projects globally. Technological advancements, such as automation and smart technologies, are enhancing the efficiency and precision of these machines, while the growing emphasis on sustainability and recycling further supports their adoption. Although the high initial investment and maintenance costs pose challenges, emerging markets and the rising need for road rehabilitation present valuable opportunities for market expansion. Leading players, including DEERE & COMPANY (Wirtgen Group) and Caterpillar Inc., are at the forefront of innovation, ensuring the market’s dynamic evolution in the coming years.

Lawrence John

Prudour

+91 91308 55334

Lawrence@prudour.com

Visit us on social media:

Facebook

LinkedIn

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.