Bionetics' retrofit boosts condenser efficiency, cutting pressure, improving air removal, & raising cleanliness from 72% to 95%.

WESTERVILLE, OH, UNITED STATES, March 17, 2025 /EINPresswire.com/ -- The Bionetics Corporation, a leading manufacturer of the Rheotherm® and RheoVac® products and associated services, has successfully addressed long-standing inefficiencies in a Westinghouse-designed "starburst" tube bundle by delivering a groundbreaking retrofit solution. This transformative retrofit solution significantly enhances condenser performance by optimizing heat transfer, reducing condenser pressure, and improving immunity to air in-leakage. This innovative approach marks a major advancement in power plant efficiency and reliability.

The Challenge: Chronic Inefficiencies in Starburst Tube Bundles

Westinghouse’s starburst pattern tube bundle has historically suffered from performance limitations due to the ineffective removal of non-condensable gases. These inefficiencies, primarily caused by low vapor velocity and air accumulation in the steam space, have led to substantial heat transfer losses. Studies indicate that traditional starburst tube bundles underutilize 15% to 25% of their condensing surface area, contributing to higher operational costs and reduced plant efficiency. This underutilization was primarily due to:

1. Low Vapor Density: Thermal resistance created by low flow of water vapor and non-condensable gases inside the air removal section results in inefficient condensation.

2. Air-Non-Condensable Gases Accumulation: Air and non-condensable gases accumulated inside the steam space, away from the air removal section, reducing the overall effectiveness of the condensation process.

Recognizing these persistent issues, Bionetics designed a retrofit solution to recover lost surface area, enhance air removal efficiency, and optimize condenser thermal performance under varying operating conditions.

The Solution: Bionetics’ Innovative Retrofit Design

Bionetics’ retrofit solution focuses on improving the steam/air dynamics within the condenser. Key modifications to the Air Removal Section (ARS) significantly enhance air removal efficiency, leading to a lower condenser back pressure and better overall performance.

In 2013, Bionetics collaborated closely with plant personnel to monitor and analyze condenser performance. In 2015, advanced instrumentation, including real-time sensors measuring circulating water temperature, condenser pressure, and total water flow rate, provided comprehensive performance insights. In 2020, the installation of High-Density Temperature Arrays (HDTA) enabled precise thermal mapping, further identifying and addressing air binding locations before and after the retrofit.

Key Performance Improvements

The Bionetics retrofit solution yielded measurable and impactful performance enhancements:

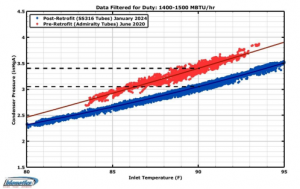

1. Reduced Condenser Pressure: Although stainless-steel tubes (which lowers the heat transfer coefficient by 16%) were used, the retrofit resulted in lower back pressure post-installation. This improvement enhanced system efficiency, reducing the unit trip risks, particularly during peak load conditions in warmer months.

2. Enhanced Cleanliness Factor: The retrofit increased the maximum achievable cleanliness factor from 72% to 95%, demonstrating a substantial improvement in heat transfer efficiency.

3. Eliminated Air Binding Issues: Post-retrofit HDTA data confirmed that significant air binding areas, previously problematic, were effectively eradicated. Even with air in-leakage at 60 SCFM, no major air accumulation was detected, showcasing the retrofit’s effectiveness in mitigating air-related performance degradation.

4. Improved Immunity to Air In-Leakage: Air in-leakage testing conducted before and after the retrofit underscored the dramatic improvement in condenser stability:

a. Pre-Retrofit: A 60 SCFM air in-leakage caused a 5-6% cleanliness factor degradation and an increase in condenser pressure of 0.1 to 0.3 in. HgA.

b. Post-Retrofit: Cleanliness factor degradation was reduced by only 1-2% at 60 SCFM, while condenser pressure increase was minimized to just 0.05 to 0.1 in. HgA.

These results highlight the retrofit’s ability to maintain performance even under challenging conditions.

A Game-Changer for Power Plant Optimization

Bionetics’ retrofit solution successfully addresses the chronic performance issues associated with the original starburst tube bundle design. By optimizing steam/air dynamics and enhancing air removal efficiency, this breakthrough technology delivers:

1. A maximum cleanliness factor improvement from 72% to 95%.

2. Greater resistance to air in-leakage, minimizing operational risks and improving plant reliability.

3. Lower condenser pressure, ensuring stable operations under varying conditions.

For more information on how Bionetics can enhance your condenser performance, contact us at sales-flow@bionetics.com or visit www.bioneticsflow.com.

Jason Reynolds

Bionetics Corp

+1 740-788-3848

email us here

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.