Armando Sanchez with 50 years mining expertise, recognized the DPM SMART mining platform could break the minus 3% downward spiral in U/G mining productivity.

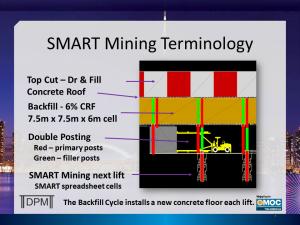

TORONTO, ONTARIO, CANADA, May 11, 2021 /EINPresswire.com/ -- DPM Mining Inc. is pleased to thank the key individuals that helped design SMART test mining program. The easiest way to understand SMART mining is to visualize an orebody is a large underground car parkade. The volume of ore between 4 posts on a parkade level becomes a cell in the SMART spreadsheet. Each cell has dimensions of 7.5m x 7.5m x 6m high containing ~1,000t of ore. See Image 13 for SMART details.

SMART creates a true expert mining system. As you mine an orebody downward in 6m lifts the SMART cell database becomes more and more accurate. All cell data is re-kriged whenever the geological 3D block model is rerun improving the data accuracy of remaining unmined SMART cells. The SMART mining method creates the 6m high spreadsheet as posts are installed at the surveyed corner of each 3D cell. Mining 15m wide panels under a concrete roof eliminates falls of ground thus generates major improvements in mining productivity, safety, working conditions with less dilution and higher ore recovery.

SMART mining is not just a patented concept. Armando Sanchez, Director of Mining for Penoles had his mining engineers search the world for a new, more productive mining method. DPM mining was identified by Javier Berumen. Wardrop now Tetra Tech was retained to do a feasibility study.

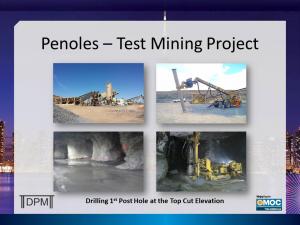

This led to the successful Golder FLAC 3D modelling which encouraged Penoles to proceed with a 4 year $5,000,000 ?proof of concept? program at the Madero mine in Zacatecas. See Images 14 and 15 for Madero pictures.

The key members of the test mine team were:

1. Armando Sanchez, Director of Mining, Penoles was the key miner that recognized that a disruptive mining method was required to break the unrelenting downward 3% productivity trend. Octavio Alvidrez Madero General Manager and Javier Berumen Assistant Mine Manger volunteered Madero to host the test mine. Octavio is now CEO of Fresnillo Plc and Javier is Assistant VP Mines for Penoles Southern Division. Armando retired at the age of 73.

2. Charles Gryba P. Eng. Invented the DPM mining method, now called SMART mining. Charles was involved with all aspects of the test mining project, including Golder modelling, CEMEX CRF testwork, 24? Cubex ITH drill design, plus the CRF plant, floor steel and instrumentation design. Gryba applied for the key patent on how to set up the continuous steel reinforced concrete floors.

3. Ivan Arriagada - Mining Engineer, Chilean, speaks Russian, Spanish and English. 905 252 0404, email ivan.arriagada007@gmail.com. Ivan owns EDC Mining, previously 20 years with Aurora Quarrying, coordinated the DPM test mining with Penoles. Ivan has designed and provided shaft supervisors for the sinking of 15 mine or ventilation shafts for both Fresnillo and Penoles.

4. Michael Arriagada ? Mechanical Engineer ? 10 years in the steel industry than 7 years with EDC. Speaks Spanish and English ? 647 987 4560, email arriagadadavida@gmail.com. Ivan and Michael designed the DPM posts, post casting system plus other test mine components using AutoCAD and / or solid works. Michael, Tony and YieldPoint installed the geotechnical instrumentation.

5. Tony Araya ? expert miner and trainer. 807 633 7921, tonyaraya@live.ca. Chilean born contract miner, worked for Aurora Quarrying on a wide range of mine contracting work then 10 years mining with Goldcorp. Tony supervised the DPM project at Madero from ramp access development through to 15m wide paneling under the concrete roof.

6. Joe Carvalho PhD ? Golder, Toronto, 647 280 7378, jcarvalho@golder.com. Joe set up the FLAC 3D model to computer mine 10 runs of various % CRF and paste fill, 45 days of continuous computer calculations. Joe translated the 3D results to successfully model the SMART softened structural design, post loading plus floor steel tensile and shear loading. Jammed 500MPa, 6% cement CRF was chosen as the optimum CRF strength for test mining. .

7. CRF testwork ? Grethel Martinez, CEMEX laboratory supervisor Mexico City. 011 52 55 5626 8379 or email grethelguadalupe.martinez@cemex.com, Grethel supervised the CRF testwork, confirming 6% cement hard limestone or 8% cement clay oxidized limestone would meet Golder?s CRF specifications. CEMEX also provided bulk cement, operated the CRF plant and caste the DPM posts.

8. Todd Hawkinson Technical Consultant Wire Reinforcement Institute, specialist in designing concrete bridge decks and deep sewer trenches. 314 807 4386, thawkinson@wirereinforcementinstitute.org. The most complex technical problem to solve was the floor steel design. Todd's solution was 1 layer of sheets of welded steel rods with 2 layers only near the posts.

9. Andrew Hyett PhD - YieldPoint ? Kingston Ontario. 613 531 4722, email andrew@yieldpoint.com. Andrew designed and manufactured the instrumentation package including a new 3D load cell that measures the CRF load changes.

10. Robert Ober and Associates ? 210 569 9262, robert@robertober.com. Concrete expert, design & build contractor for CRF, ready mix and casting plants, built the 6,000tpd CRF plant for Barrick at Cortez.

11. Mauro Dobran ? Chief designer, Cubex Winnipeg - now Sandvik, Chile. 56 2 26746 0294, mauro.dobran@sandvik.com. Mauro designed and manufactured the automated 24" diameter Cubex ITH drill with a 6m mast and 2,000cfm compressor.

12. Pat O?Connel ? Proconsul Mining Associates - explosives expert for 40 years ? blasthole mining, shaft sinking, ramping and open pit blasting. Pat and Tony designed the drill pattern for safe blasting under the concrete roof. 705 264 3502, oconnell@vianet.ca

Gryba is now concentrating on increasing the mining EHS awareness of this disruptive SMART mining technology. SMART triples mine productivity, improves miner safety & creates a shop like work environment underground. Elimination of falls of ground makes automated mining, battery or robotic equipment, mechanical cutting and tele remote mining more viable. Elimination of waste rock and backfill dilution combined with higher productivity substantially increases the orebody NPV.

Rather than keeping SMART technology confidential 10 EIN press releases will be issued to explain SMART to both the mining and financial market. To quantify some of the 40 SMART platform advantages, 4 well known mines will be redesigned using SMART.

Charles Gryba

DPM Mining Inc.

+1 416-801-6366

email us here